Metso Flow Control Oy

As part of the risk assessment for a high-pressure valve testing facility, Metso Flow Control Oy wanted to simulate the case of valve failure and the results of the blast impact and detached fragments on the surrounding walls.

The goal is to determine the required thickness of the steel plate in the test facility safety walls. The penetration of any fragment or rupture of the safety wall is not allowed in the analyses.

Case 1: Impact analysis of detached fragments

Case 2: The minimum wall thickness is evaluated also by the explosion analysis.

Solver: The analysis type is explicit dynamic analysis using LS-Dyna.

Case 1: Given the maximal specified test pressure, and the detached fragment properties, the initial velocity of the fragment was calculated analytically and used in the impact analysis. The flight path of the impacting fragment is chosen to be normal to the wall.

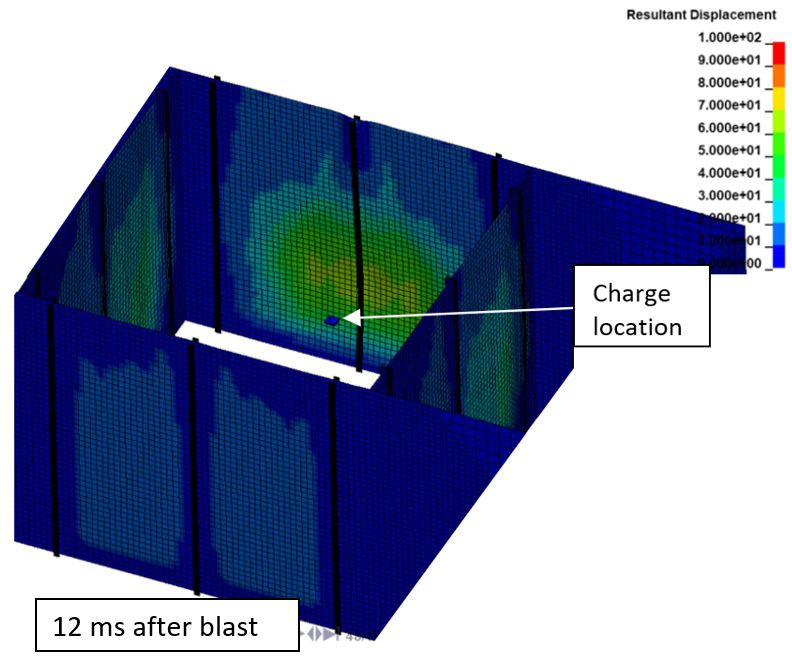

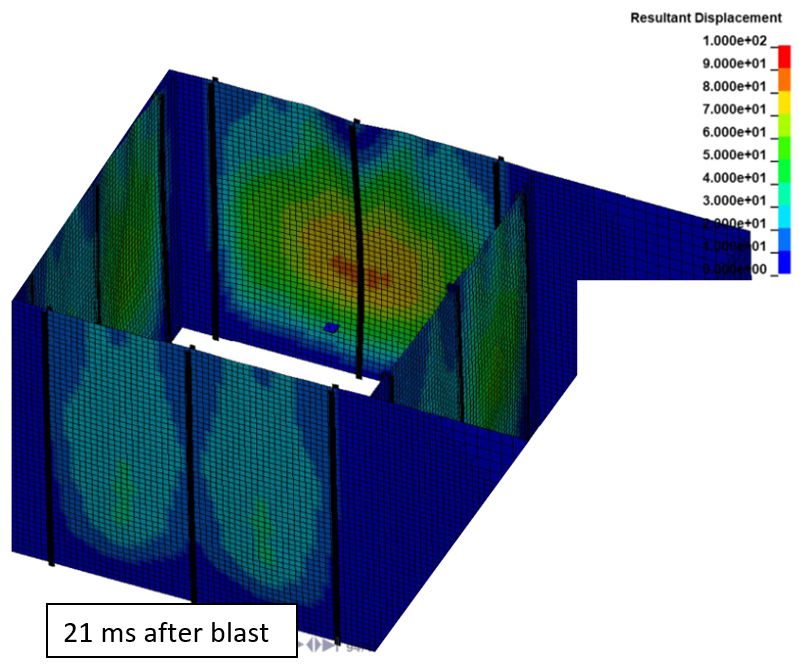

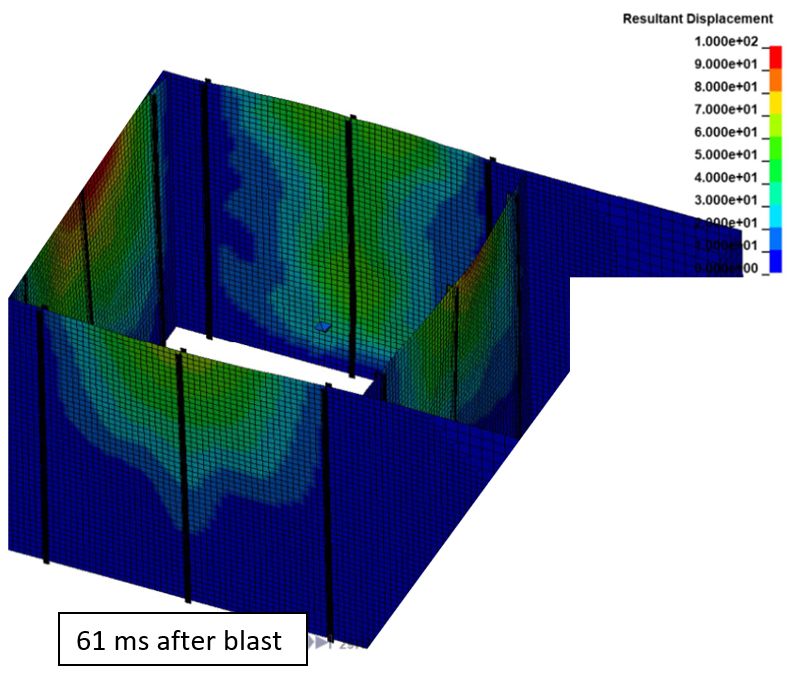

Case 2: The load model “ConWep” (Conventional Weapons Effects, LS-dyna) is used to generate the colliding pressure wave. The explosion energy is calculated according to the compressed gas energy for ideal gases. In the FEM analyses, the same explosion energy is generated using the equivalent amount of TNT.

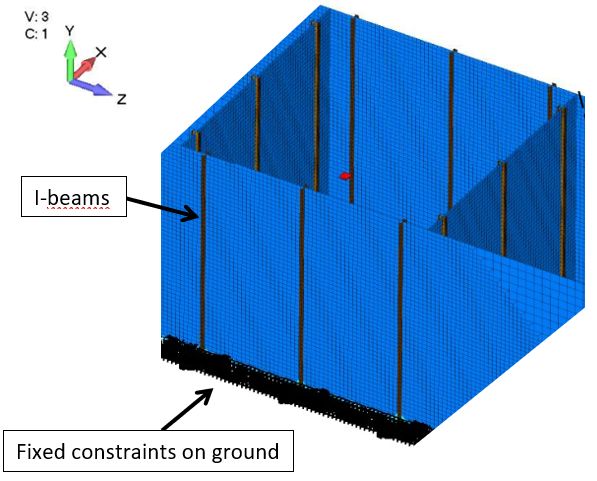

FE-model of the test facility.

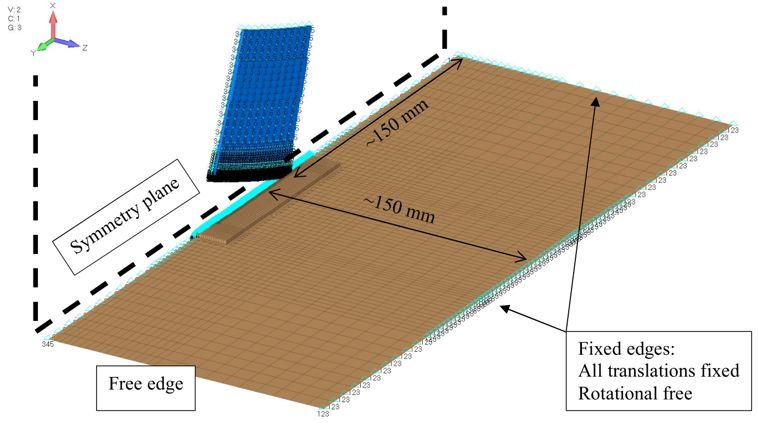

Boundary condition in the FE-model of impact analysis.

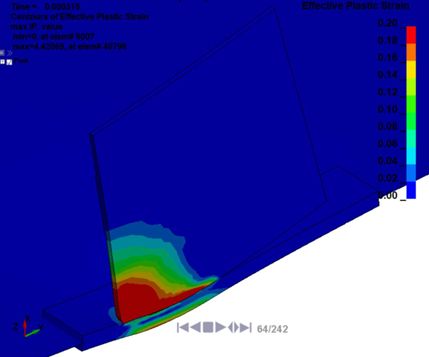

Case 1: Detached fragment impact on sidewall. Contours of effective plastic strain. Fragment does not penetrate the wall.

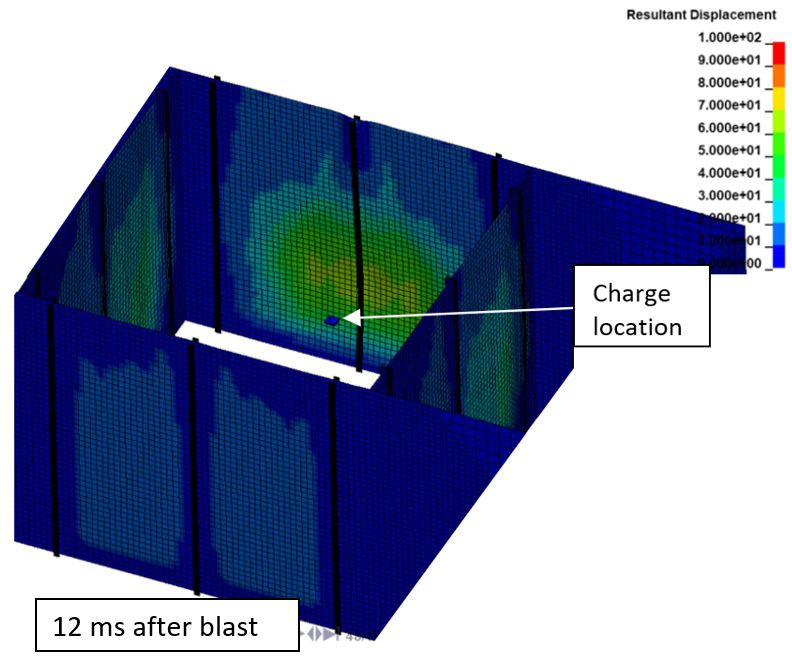

Case 2: Total displacements as a function of time. The walls are able to withstand the blast load.

Uutiskirjeessä avaamme laskentamaailman saloja helposti ymmärrettävässä muodossa. Tavoitteemme on tuottaa hyödyllisiä tietoiskuja sekä lujuus- että virtauslaskennasta. Uutiskirje julkaistaan noin 2–3 kk välein ja se ovat mahdollista perua milloin tahansa.